Seattle Basement Bath: Smart UPC DWV Plan

Question

I’m renovating a surprise basement bathroom in Seattle.

All drains are under the slab and tie into the kitchen stack.

I drew a plan, but I worry about the slope and the horizontal vent.

Specifics:

- Where should the end-of-line cleanout go?

- Can I use a Fernco to join PVC to a galvanized vent?

- Is my horizontal wet vent legal under the UPC?

- All vents and fixture drains are 2″; the main is 3″.

Answer

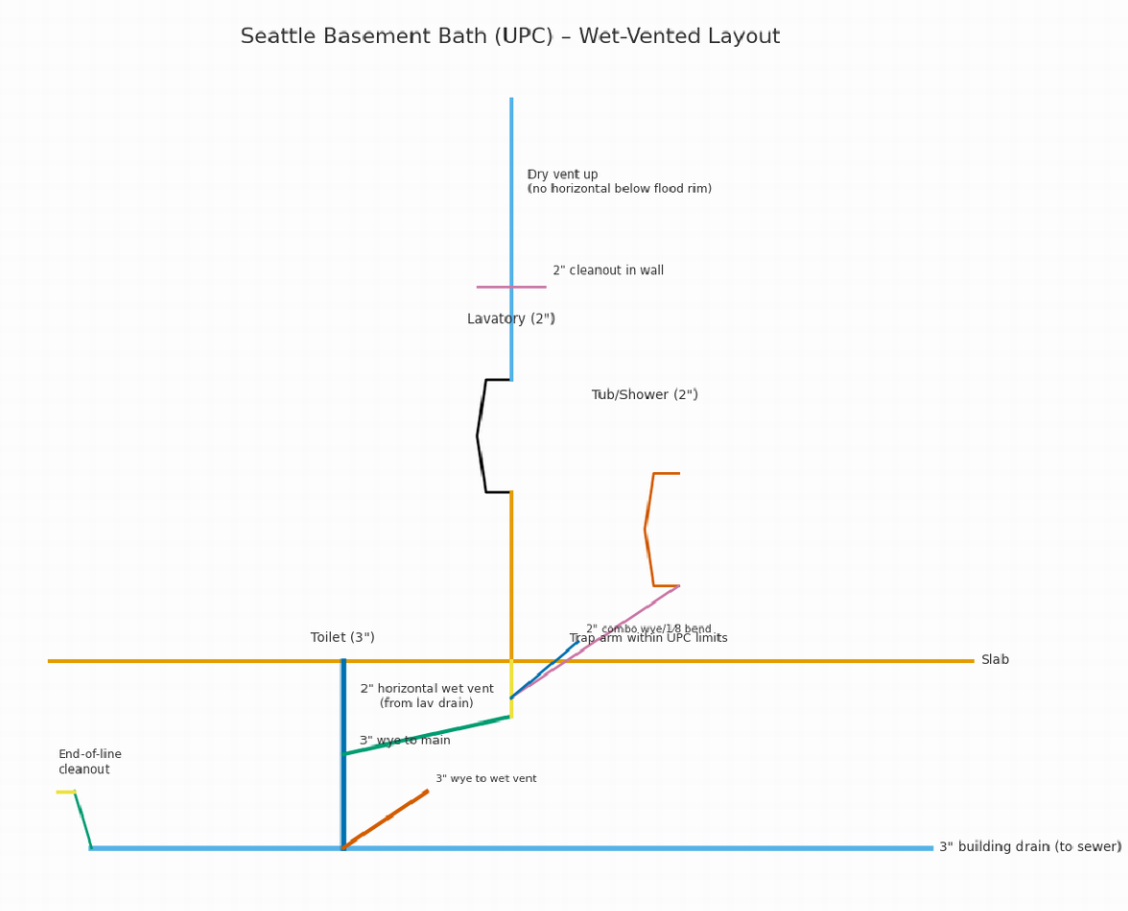

Use a 2″ lavatory drain as the horizontal wet vent for the bathroom group, keep the lav’s dry vent vertical until at least 6″ above the flood rim before any horizontal, provide an accessible 3″ end-of-line cleanout and a cleanout at the base of the vent, and use a shielded transition coupling (not an unshielded rubber sleeve) to join PVC to galvanized above ground.

Cleanouts that pass inspection

- Install a 3″ cleanout at the upstream terminal of the 3″ branch (often left of the toilet, in a wall or a floor box).

- Add a 2″ cleanout at the base of the lav vent (accessible in the wall).

- Provide cleanouts at changes in direction exceeding 135° and every long run as required.

- Maintain the required working clearance in front of each cleanout.

Wet venting under the UPC (Seattle)

- Horizontal wet venting is allowed for one bathroom group on the same floor.

- Run the lavatory drain in 2″. That pipe is the wet vent serving the toilet and tub/shower.

- Use a 3″ closet bend and wye into the 2″ lav wet-vented line, then to the 3″ main.

- Keep the lav’s dry vent vertical to 6″ above the highest flood rim before any horizontal run.

- Hold ¼″ per foot slope on under-slab horizontals and avoid bellies.

Joining PVC to galvanized above-ground

Use a shielded transition coupling (often labeled “Proflex” or “shielded no-hub”).

Unshielded, all-rubber sleeves are typically for underground only and are not approved above ground.

Practical tips before you cut concrete

- Verify the existing 3″ tie-in elevation to confirm slope availability.

- Use long-sweep combos for under-slab joins; avoid hard 90s.

- Respect trap-arm limits and vent sizing per UPC and local amendments.

- Sketch pipe depths on the slab to plan trench width and clearances.